Steel Belt Casting And Drying System

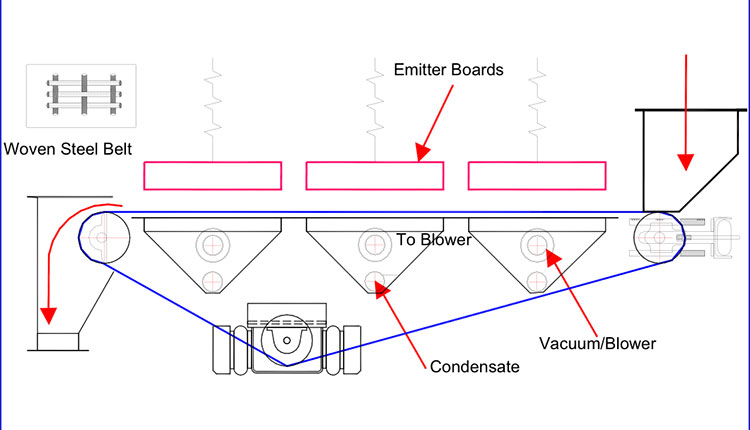

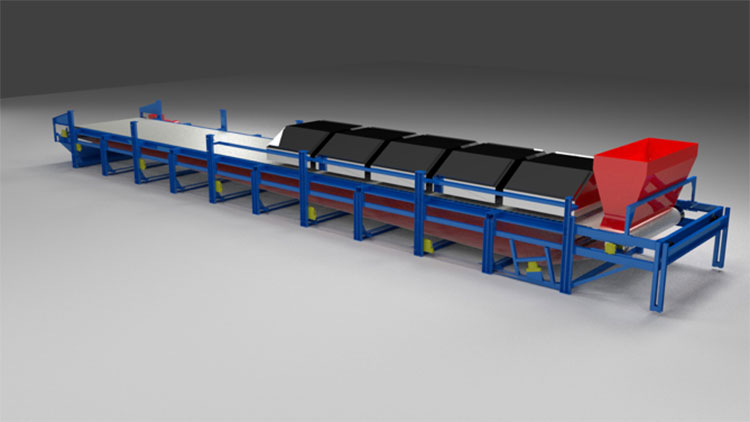

Steel belt casting and drying system. Search for used steel belt casting drying systems for sale on Machinio. Then steel belt conveys the materials to the drying tunnel furnace which is heated by PTC and quartz heating pipe water vapor is carried away by the air circulation dehumidification system. In this process a polished steel belt is coated.

Belt dryers extract all moisture from sheets powders flakes fibers or wet materials such as sludge prior to production. For more than 20 years Berndorf has been manufacturing complex machines including. They manufacture high quality stainless carbon and titanium steel belts.

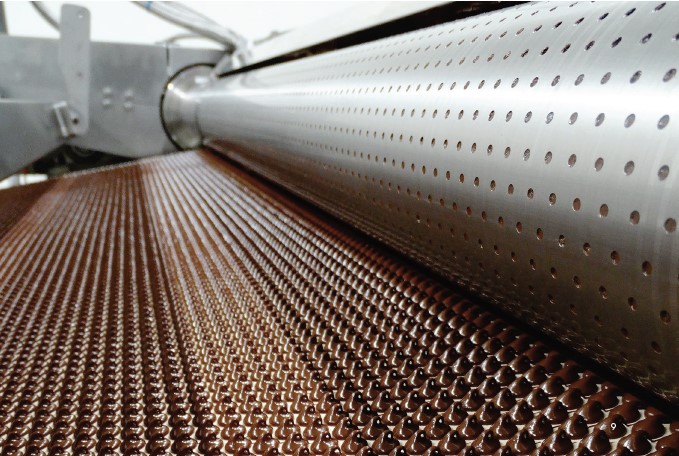

Watered materials are evenly spread on the steel belt conveyor system through spread machine. They also produce machinery like double belt presses casting and drying systems and provide servicing for it. This is why our steel belt casting and drying systems allow for the precise and high-quality production of foils and films.

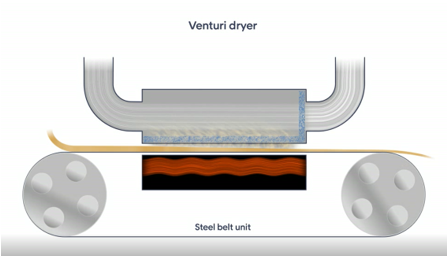

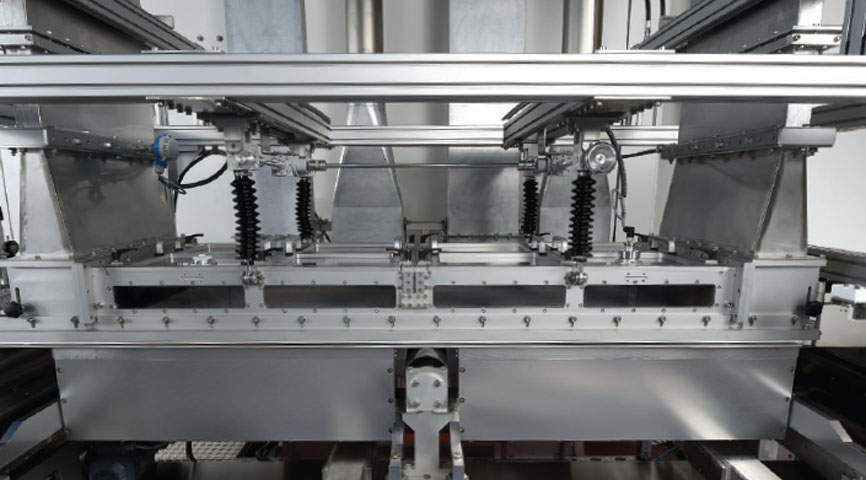

The cast layer is then transported on the polished steel belt through the Venturi drying unit to achieve a stable high quality product in an extremely efficient manner. The Berndorf Band Groups engineers combine their long years of experience and profound expertise with state-of-the-art technology. Steel belt casting and drying system for the production of solvent based films foils.

Precipitation sections for the membrane manufacturing. Continuous production capacity. The steel belt dryer can not only dry the material but also can do process like baking or cooking.

Get to know more. ISO 9001 ISO 14001. Steel belt casting and drying system for the production of solid surfaces like artificial marble.

Design and manufacturing of steel belt systems for continuous industrial processes. The material is scraped off the steel belt by a scraper at the.

Steel belt casting and drying system for the production of solvent based films foils.

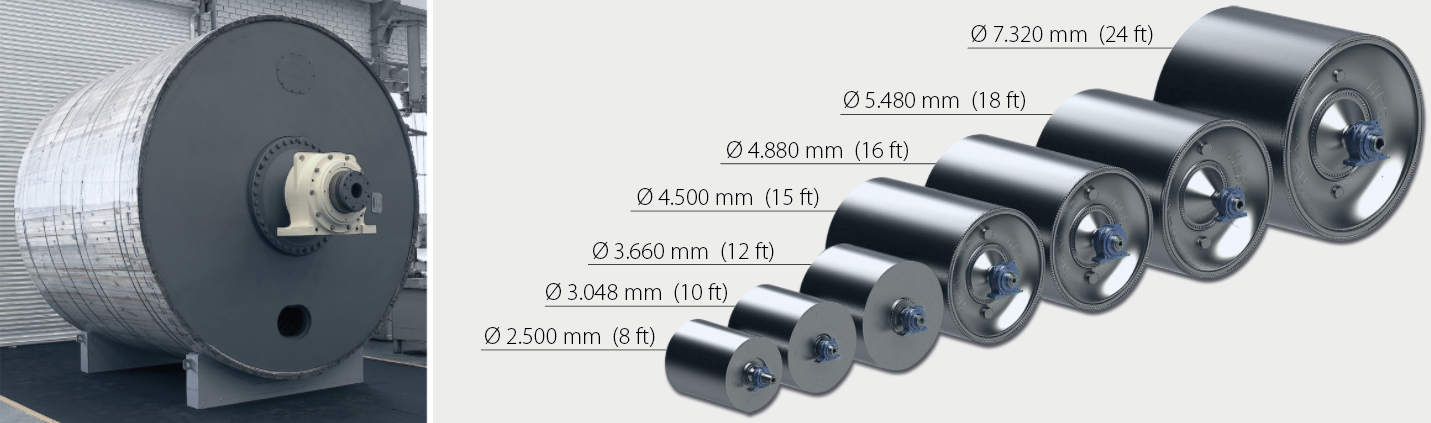

Consol Steel Belt Conveyor System CONSOL is an international enterprise focusing on steel belt and steel belt driving systemincluding the food industry chemical industry composite industry rubber industry film casting industryetc. Our single belt film casting units offer a range of benefits including ultra-efficient continuous production and the ability to cast very thin films to fine tolerances. Then steel belt conveys the materials to the drying tunnel furnace which is heated by PTC and quartz heating pipe water vapor is carried away by the air circulation dehumidification system. The Berndorf Band Groups engineers combine their long years of experience and profound expertise with state-of-the-art technology. Application systems like slot dies from TSE Troller. SBS Steel Belt Systems. The material is scraped off the steel belt by a scraper at the. Our sulphur solidification technology is able to supply Complete Packages. Steel Belt Casting and Drying Systems Machine Components Special Machines Steel Belt Cooler Accreditation Licenses Certifications Certified IQNet Management System Quality Austria System Certified.

The cast layer is then transported on the polished steel belt through the Venturi drying unit to achieve a stable high quality product in an extremely efficient manner. Applications for steel belts in the chemical industry include casting polymerizing of resins waxes para fins and many other substances. Our single belt film casting units offer a range of benefits including ultra-efficient continuous production and the ability to cast very thin films to fine tolerances. For more than 20 years Berndorf has been manufacturing complex machines including. Our sulphur solidification technology is able to supply Complete Packages. One special type of the casters made by Berndorf Band Group are dependable manufacturing systems for a variety of solid surface materials like artificial marble. Steel belt casting and drying system for the production of solvent based films foils.

Post a Comment for "Steel Belt Casting And Drying System"